Thermo- and hygrometer as Christmas presents

Background

Last year I gave away homemade picture frames for Christmas. I had a lot of fun making them and so I decided again this year for something I made myself. At some point, a box with these electronic modules (picture) ended up on board c-base in mysterious ways. These modules were once intended as very accurate thermo- and hygrometers, which recorded the data precisely and court-proof, so that in case of “mold in the living room” a objective data set about the humidity, temperature and frequency of airing the rooms exists. In other words, a device that is used in the legal relationship between tenant and landlord. These devices are not available since approx. 2006 any more.

At some point, a box with these electronic modules (picture) ended up on board c-base in mysterious ways. These modules were once intended as very accurate thermo- and hygrometers, which recorded the data precisely and court-proof, so that in case of “mold in the living room” a objective data set about the humidity, temperature and frequency of airing the rooms exists. In other words, a device that is used in the legal relationship between tenant and landlord. These devices are not available since approx. 2006 any more.

Project

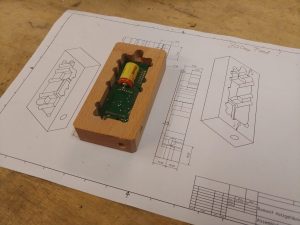

A member of c-base analyzed the hardware and developed a new software that reads the sensor, which is very accurate in itself, and displays the data without saving it. A special feature of this device is the battery – a so-called lithium thionyl chloride battery, which has been replaced. This special type of battery has a particularly low self-discharge and is the means of choice when tiny amounts of electricity are required over very long periods of time (decades). Such a battery only emits so little current that you could even short-circuit it for several weeks without damaging the battery.

Fortunately, the member who created the new software is a bit of a perfectionist and has optimized the software for even lower power consumption in recent months – with the current software version, a battery should last about 17-20 years. The software is published here.

The sensor is of particular precision, which is shown in particular by the fact that the cumulative measurement error (the development of the systemic deviation over the lifetime) remains very low over decades. I can’t say whether the instrument displays 0.5-1°C too much or too little, but it is certain that a calibration error will remain relatively static and will hardly worsen.

Implementation

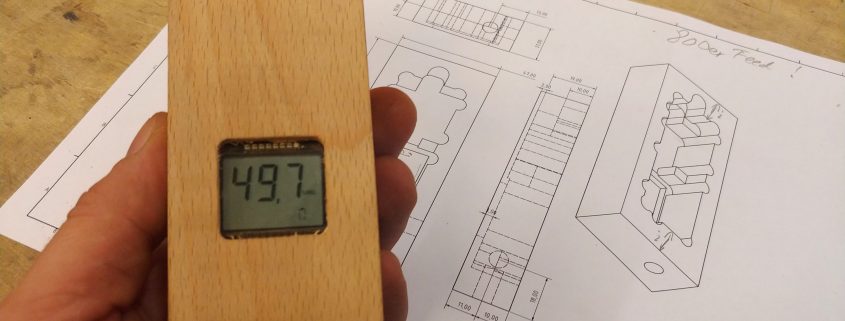

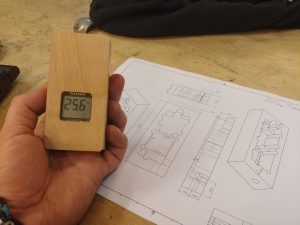

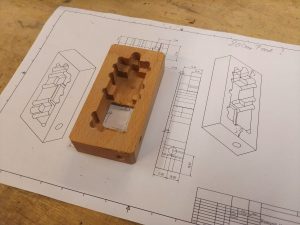

On the basis of the hardware I developed a housing shape, which can be milled with the self-built CNC milling machine c-nancy. I used the same wood as for the picture frames – a red beech. Probably the wooden parts even come from the same tree.

The first version of the case fit only poorly, especially corrections around the display were necessary, so that only the relevant part of the display is visible and not parts of the electronics around the display. The technical drawing of the case is here: Romonit-Holzgehäuse.pdf.

The second version, in which the display cut-out was significantly reduced in size, then fitted in and went into production.

The mounting of the electronic components was done with tiny screws – M1,4x8mm, for which I needed special drills with a diameter of 1,2mm to pre-drill the holes for the screws, because the red beech was too hard. I also tried to pre-drill only 1.0mm, but then tore the screw off trying to force it into the hole.

Project

I still don’t know if all the thermometers have reached my relatives in time, at least they all worked at the time of shipment.

For this project I made a video in which I tried a new video style. I don’t have a name for this style yet, but it is characterized by very long shots, little depth of field (bouket) and a very relaxed musical background. The goal was to make a video with a style similar to the #ASMR category, even though the use of the machine probably stands in the way.

Pictures

I also took some more pictures of this project.