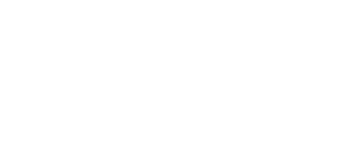

Line bender for thermoplastics

Background

For the laser fence project vacuum formed plastic pieces had to be bent. The flat panels should form a hollow body which is initially closed just on four sides by three (four) paralell bends. The first tests were carried out with aluminum profiles, clamps and a hot-air gun. The precision of this technique was not sufficient, so a better bending tool was necessary.

After a quick research I found this Video, from which I let my self be inspired.

Construction

This device was completly made from in-house materials, I did not need to buy anything. We used:

- Particleboard covered with Melamin

- 2 Hinges

- 12mm Birch Plywood Leftoverpieces

- 1m heating wire

- Old AT PSU

- Switch

- Cables

- Cable ducts, various small pieces

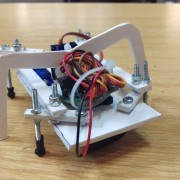

In the middle of the device is an aluminum U-profile, open at the top, in the middle of it is the heating wire strung, which is tensioned with springs. The aluminum profile comes up against both sides of the particleboard, one of which is firmly secured, the other only by means of hinges. The axis of rotation of the hinges is located vertically a few millimeters above the heating wire.

An AT-Computer PSU was used as power supply. This device is limited to 12V/8A, in my opinion this is on the lower end of a reasonable power output.

On the left side of the device is the PSU and the switch located, on the right side there is an adjustable angular stop, which allows to pre-set the target angle of the bend

Application

In the initial position both particleboard are lying flat on the base plate. A workpiece is placed and the power for the wire is turned on. After about 30 seconds the top (the side facing away from the heating wire) above the wire is noticeably warm to the touch. After another 10 seconds, you can slowly start to raise the movable particleboard while firmly pressing the workpiece against the fixed plate. If the material is hot enough, it will significantly bend at the designated location and the force required decreases, the farther you have bent the workpiece.

When the movable platen reached the angular stop, which should be set about 2-4° further then the desired target angle, the user operates the switch to power off the wire. After about 30-60sec the bend is sufficiently cooled and the workpiece can be removed from the line bending machine.

When the movable platen reached the angular stop, which should be set about 2-4° further then the desired target angle, the user operates the switch to power off the wire. After about 30-60sec the bend is sufficiently cooled and the workpiece can be removed from the line bending machine.

Success

An impromptu version was made for the preparations of 32c3 which worked. Immediately after 32c3 I have replaced the improvisations by mechanically sound and durable solutions. The total cost amounted to 0 €, all the parts came from in-house means.